[ad_1]

Whether you’re a crafter in need of more time or a business ready to mass-produce goods, the Cricut Autopress offers a distinct advantage. With the Cricut Autopress’ operating motors keeping your design pressed and in place via transfer, there’s a chance to speed up your preparatory workflow or simply offer your body an additional moment of reprieve. While this may not be enough to sway you from Cricut’s previous presses, it offers a welcome shift to make crafting tech even more inviting.

- Largest Cricut Heat plate thus far: 15 x 12 inches

- Just two fingers to close

- 62 degrees of visibility when open

- One touch presets for time and temperature

- Brand: Cricut

- Dimensions: Closed: 16.63 (width) x 6.62 (height) x 26.07 (depth) inches | Open: 16.63 inches (width) x 25.14 (height) x 23.21 (depth) inches

- Weight: 53.2 lbs

- Connectivity: USB (USB-A, microUSB)

- Display: Yes

- Storable presets allow for convenient start-up and adjustment

- Less strain on your body thanks to its motors

- Auto-adjustment to different materials makes for cleaner presses

- Automatically opens upon completion

- Time-saving

- Smaller heat plate relative to other commercial presses

- Control pod dials can sometimes overshoot your desired value

The Cricut Autopress aims to take away the struggles of a regular heat press. By introducing both automation and time-saving measures, you’re able to undertake heat transfer projects much faster. But not all designs transfer the same, so how does the Cricut Autopress handle a variety of jobs?

Cricut Autopress Set-Up

With Cricut’s products, if there’s any caveat to entry, it’s the set-up process for the specific product you have.

For the Autopress, it’s not Bluetooth enabled like the EasyPress 3. If you’ve grown accustomed to using the Cricut Heat app, you’ll have to forgo it for now. Instead, you’re going to connect the Autopress control pod to your computer using the included USB cord and set-up via Design Space.

From here, it’s a very similar process to setting up any of Cricut’s other machines. Using Design Space, you’ll follow very simple but clearly visualized prompts of every step of the set-up process. After the Autopress downloads any updates, you’ll remove the USB cable from the computer, connect it to the Autopress, and complete activation by unlocking and powering it on.

Overall, it’s a very simple procedure but one that’ll also familiarize you with the cabling and ensuring they’re securely fitted to the back of the Autopress unit. If you attempt to bypass the set-up process, however, you won’t be able to use the device. Instead, the control pod’s display will prompt you to connect it to your computer.

Cricut Autopress Technical Specifications

In terms of what you’re getting with the Autopress, what is there?

Foremost, you’re getting the largest heat plate available from Circuit. The Cricut Autopress’ ceramic-coated heat plate measures out to 15 x 12 inches (38 x 30 centimeters). Whether you’re still using the Cricut EasyPress 2 or EasyPress 3, you’ve been previously capped at 12 x 10 inches (30 x 25 centimeters) for your maximum press area.

For heat distribution, there’s still the familiar edge-to-edge heat of up to 400 °F (205 °C) to cover a wide range of materials. To reach the maximum, the Cricut Autopress takes approximately eight minutes to go from room temperature to 400 °F. So if you’re looking to quickly power it on and do some prep work, you won’t be waiting long.

What will entice most, however, is its means to apply automatic pressure to your transfers. After loading your project onto the Cricut Autopress, all you have to do is lower the heat plate and gently press down on the handle. The Cricut Autopress will engage its motors and automatically adjust to materials up to 2 inches (5 centimeters) in thickness and will automatically open once the timer goes down.

Cricut Heat Press Safety Measures

As one would expect with a device capable of generating high temperatures, there’s a variety of ways to keep you informed and safe while operating it. First off, the Autopress is built with certified temperature-rated plastics to endure repeated presses. There’s also a built-in fan to channel the flow of air to direct heat away from the handle during operation.

The Cricut Autopress also opens up to a wide 62° angle. With the extra wideness, there’s more room to maneuver your project and avoid any potential accidental contact with hot contact surfaces. Once you’ve finished using the Autopress, you also don’t have to wait for it to cool down, and you can instead return it to its initial locked position for cooldown where the press isn’t exposed.

At the very front of the unit by the handle, there’s an LED indicator that’ll inform you of what’s going on with the Autopress. If it’s orange, the unit is heating up, green indicates it’s ready to use, and it’ll turn red if the machine is locked or the controller pod has been detached. Like Cricut’s other heat presses, the Autopress will automatically shut off after thirteen minutes of inactivity while offering a warning beep and a sleep message on the control pod before turning off.

Storing and Placement for the Cricut Autopress

As a smaller heat press, it’s small enough to fit on a small counter with it measuring out at 16.63 (width) x 6.62 (height) x 26.07 (depth) inches. But if you need to move the Autopress, you can use the handle and the handhold at the back of the unit. If you need to move it beyond the expanse of a room, I’d advise holding it from the bottom and using the handhold for a better grip instead.

Similarly, the Autopress can be stored vertically on its base. Since the Cricut Autopress is evenly balanced, it can fit alongside a table or in a small gap quite comfortably. However, if you’re wanting to keep the unit more pristine, you’ll have to account for any dirt it might acquire via this storage method.

Preparation With the Cricut Autopress

Batch production is a major focus area of the Autopress, so a related question is what helps with this. If you own either the Circuit Explore 3 or Maker 3, you’re still able to process smart materials of up to 12 feet long. While you can still easily take advantage of older Cricut machines and Cricut mats, mass-cutting designs can naturally intermingle into batch presses with the Autopress.

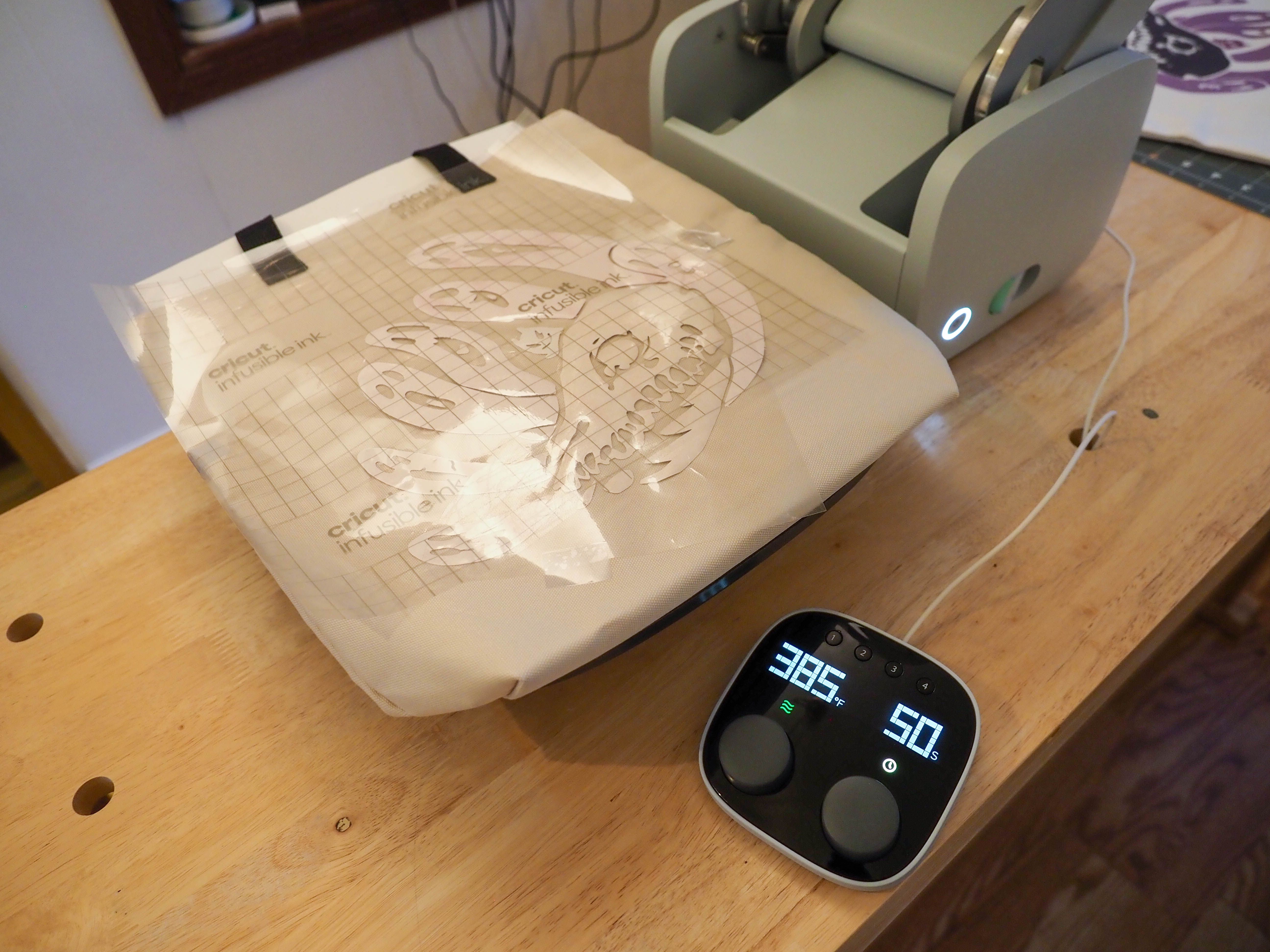

Regardless, if you’re looking to save a little time with production, Cricut is looking to simplify its overall ecosystem to get you making faster and save you some strain in the process. To test this, I tried both smart materials and more of Cricut’s infusible ink. Also, I used both Cricut blanks and independent materials to test the transfers using the guidelines across the Cricut Heat app or Cricut’s heat guide.

While I had very consistent results with an assorted mixture of heat transfer material and surface, the Autopress’ features shine most of all with a consistently-produced batch item. Given that t-shirts offer a variety of variables to consider across their sizes, sleeve type, and more, I decided to test out batch production via the Autopress using them. To this end, I used Cricut’s smart iron-on to capitalize on the available 9-foot rolls to produce large design cuts.

In terms of results, I’d get around seven 15-inch designs to work with consecutively with the Autopress per roll of material. Any leftover scraps can be used with Cricut’s mats to cut and add smaller designs or embellishments to your materials. However, when working with larger design with the Autopress, there’s some overhang you have to deal with.

Meanwhile, if you want to capitalize on some smaller isolated areas such as the sleeves of shirts or sweaters, you take advantage of the Autopress’ extra size to get a better line-up with the seams.

With Infusible Ink, you’ll still want to use both cardstock as a backing and butcher paper as a buffer to limit bleed potential. If you’re going for a multicolored design, there’s the option to cut and place different pieces on one liner. Alongside the large placement area and non-slip nature of the Autopress pressing mat, there’s ample room to position and protect as needed.

When testing with both a tote bag and pillow case blank, I noticed I was able to tweak the heat settings to get the desired finished effect with the infusible ink. While Cricut’s heating guidelines are a great first measure, utilizing heat-resistant tape and the non-stick nature of the heat plate can allow for some creative divergence.

Ultimately, preparation with the Autopress requires a bit of strategizing to get the optimal use of the plate’s size.

Using the Cricut Autopress

With Cricut Autopress, it takes as few as two fingers to get the press going, and then it takes over for the rest of the heavy lifting. Once the motors engage to apply pressure based on material thickness, all you have to do is release. For cleaner presses, the Cricut Autopress uses a hinge system to move its heat plate vertically before it entirely closes to prevent shifting or pinching of materials.

During this process, it adjusts to materials up to 2 inches thick. If you’ve ever had to continually adjust your pressure to different material types, this can definitely save your arms. Plus, once it’s finished, the Autopress will open up automatically to let you know it’s ready for the next step.

In terms of inputting your temperature and time, this is all done via the Autopress’ dials. While there’s four presets already included on the control pod, you can overwrite them by holding down on one of the four top buttons for a few seconds until a beep registers the new preset has been made.

When adjusting values via the dials, it can prove a bit too responsive and overshoot your desired value. If you inch along near the desired value, this is less of an issue. And if you’re using the four presets around your most active projects, you’ll quickly forget about making setting tweaks most of the time.

Batch Production with the Cricut Autopress

While the Cricut Autopress can be utilized for any level of heat transfer job, it was truly built for batches. Because the machine opens automatically after the timer completes countdown, you’re free to prep your next item using multiple mats. So if you’re looking to commercialize the Autopress, purchasing a second (or third) Cricut pressing mat can greatly simplify your job.

Similarly, there’s still the option to use your older heating maps in tandem. So if you already have one of Cricut’s EasyPress heat presses, synchronizing timing with the Autopress isn’t hard at all. With the right timing or some help, you can get a batch done in half the time or less.

For testing, I was cutting longer 15-inch iron-on designs; the Autopress has that maximum of 12 inches over the larger EasyPress heat press area of 10 inches. Both required double presses with me utilizing the EasyPress 3 with a 20 x 16 inch EasyPress mat to hold the design for comparison.

When comparing the two, you may find a larger mat may benefit a more multi-sectioned design, so you’ll want to keep that in mind. But you’ll also want to keep in mind infusible ink designs aren’t meant to be larger than the plate and require a single application of heat. If you’re looking to press larger ones, the Autopress definitely has an advantage there.

In the end, the Autopress simplifies a lot of legwork to allow you more time to think our your design and its alignment.

Should You Buy the Cricut Autopress?

With the Circuit Autopress, your decision is going to mostly hinge on your wallet. The Autopress is a professional heat press, so its price point is considerable higher than Cricut’s other presses. If you’ve been on the footstep of looking to expand to a heat press for business uses or any more frequent batch production though, it offers a variety of time-saving features that pay for itself.

It’s still a bit small compared to other commercial heat press options. So if you’re needing to single press larger designs, you may also want to look elsewhere. However, the Autopress offers automation with a relatively small footprint and storage flexibility.

However, if the Autopress works for your design sizes, it’s easy to recommend it for both its time-saving and strain-reducing results. If you want to focus more on crafting and less on heat transfer, it’s a great addition to a work area.

[ad_2]

Source link